Celazole ® T-Series

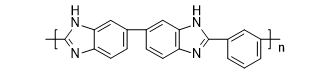

Celazole ® PBI (polybenzimidazole) is a unique and highly stable heterocyclic polymer

Celazole® T-Series products are PBI compounds designed for injection molding and extrusion. Combining the superior mechanical properties and thermal resistance of PBI with the melt process ability of polyaryletherketones (PEEK or PEKK), these products offer cost-effective high performance. These products are available in pellet form.

Celazole PBI (polybenzimidazole) is a unique and highly stable heterocyclic polymer. PBI polymers are characterized by high thermal stability; exhibit high strength, broad chemical resistance and unique compatibility with certain other polymers including the polyaryletherketone family.

TWO PROCESSING METHODS:

INJECTION MOLDING

Celazole ® T-Series pellets are capable of being injection molded on equipment with requisite thermal and pressure profiles.

EXTRUSION

Celazole ® T-Series pellets are capable of being extruded on equipment with requisite thermal and pressure profiles.

The advantage of T-Series over ordinary PEEK is the unexpected property set that results from the combination with PBI and other fi llers (when present) that yield higher heat deflection temperatures (HDT), higher moduli, higher strength, improved wear resistance and lower creep. In the T-Series composites, HDT’s can be raised to 320ºC, just below the crystalline melting point of PEEK.

A desirable balance of performance and tractability is obtained with the T-Series products that place the group’s thermo-mechanical performance above PEEK, but below PBI. T-Series is designed for injection molding of parts that perform, but are cost effectively produced.

KEY FACTS

High strength: TF-60C has 15,000 psi flex strength at 500°F (100 MPa flex strength at 260°C)

Cost effective: T-Series products are 100% melt processable

Thermal stability: enabling metal replacement

DIFFERENT GRADES:

Celazole PBI PEEK compounds

Celazole® TU-60 is a high performance unfilled blend, ideal for applications requiring no fillers. This material works well for complex geometries and offers the best process ability. It is ideal for lamp sockets, connectors and backup seals.

Celazole® TL-60 is a lube grade blend offering superior wear resistance, low friction, chemical resistance and high load bearing capability. It’s well suited for rotor vanes, thrust bearings, plane bearings, bushings and other friction management applications – particularly under load.

Celazole® TF-60C is a carbon-reinforced blend, ideal for parts that require high strength, very low creep, and deflection resistance. A great match for planetary gears, office equipment, semiconductor, electronic and mechanical applications.

Celazole® TF-60V is a glass-reinforced blend offering thermal and electrical insulation, wear resistance and dimensional stability with the cost efficiency of a direct form process. An excellent choice for high temperature electrical insulators, plasma torch drag cup shields, swirl baffles and parts requiring minimal thermal expansion.

PBI PEKK compounds

Celazole® TK-60 is an unreinforced melt processable blend of PBI-PEKK (polyetherketoneketone).

Celazole® TKL-60 is a self-lubricating melt processable blend of PBI-PEKK (polyetherketoneketone).

Celazole® TK-60C is a carbon fiber reinforced melt processable blend of PBI-PEKK (polyetherketoneketone).

suitable for various insulation applications

suitable for sealings, bearrings, glide-rings

suitable for various electrical parts

widely used in semiconductor industries

suitable for aerospace and automotive

PBI-polymer is an ultra high performance plastic developed for aviation and space-flight applications.